More Rubber to Metal Bonding Companies

What is the purpose of rubber to metal bonding?

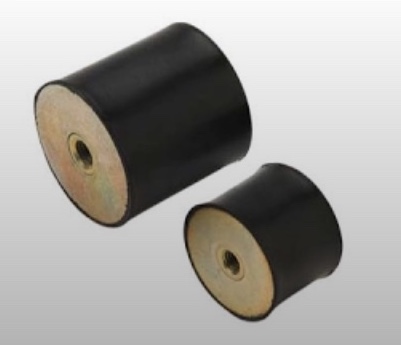

Answer: Rubber to metal bonding is a specialized engineering process used to permanently adhere rubber compounds to metal substrates. The primary goal is to harness the best characteristics of each material: the flexibility, vibration absorption, and sealing capabilities of rubber with the structural integrity, durability, and load-bearing capacity of metal. This combination results in high-performance components that can endure mechanical stresses, temperature extremes, chemicals, and environmental factors, making them indispensable for demanding industrial applications.

What is the purpose of rubber to metal bonding?

Answer: Rubber to metal bonding is a process used to create strong, durable connections between rubber and metal components. Its primary purpose is to combine the flexibility and resilience of rubber with the strength and rigidity of metal, resulting in parts that can withstand various stresses, vibrations, and environmental conditions. This technique is widely applied in industries like automotive, aerospace, and manufacturing.

For example, in automotive applications, rubber to metal bonding is used to make components like engine mounts, suspension bushings, and seals. The rubber absorbs vibrations and provides cushioning, while the metal provides structural support and stability. The bonding process ensures these materials work together seamlessly, preventing separation under load or over time.

The process typically involves surface preparation (like cleaning and applying adhesives or primers) followed by molding or vulcanization, where the rubber is chemically bonded to the metal. This creates a reliable, long-lasting part that can handle dynamic forces and harsh conditions, such as temperature extremes or exposure to chemicals. Essentially, it’s about making hybrid components that leverage the best properties of both materials.

What industries use rubber to metal bonding components?

Answer: Rubber to metal bonding components are used across a variety of industries where the combination of rubber’s flexibility and metal’s strength is critical. Here’s a rundown of the key sectors that rely on this technology:

- Automotive Industry: This is one of the largest sectors utilizing rubber to metal bonding. Automotive manufacturers employ bonded components for engine mounts, suspension bushings, vibration dampers, seals, gaskets, and anti-vibration pads. These parts are crucial for reducing NVH (noise, vibration, and harshness), enhancing ride comfort, and improving vehicle durability. Looking for ways to reduce vehicle noise and improve performance? Explore how automotive rubber to metal bonding can enhance your designs.

- Aerospace and Aviation: The aerospace sector relies on bonded parts for vibration isolators, flexible couplings, EMI/RFI shielding gaskets, and custom aerospace seals. These components help manage extreme vibrations, temperature fluctuations, and pressures encountered during flight or space missions, ensuring both passenger safety and equipment reliability.

- Industrial Machinery: Heavy equipment, compressors, pumps, and industrial machinery utilize anti-vibration mounts, flexible couplings, bonded rollers, and bearing seals. These components extend equipment life, reduce maintenance downtime, and improve operational efficiency in high-load, continuous-use environments.

- Construction and Heavy Equipment: Construction vehicles, cranes, excavators, and earth-moving machinery use rubber to metal bonded shock absorbers, seals, and isolators to withstand dynamic forces, harsh outdoor conditions, and abrasive environments. Need to improve machine longevity? Learn more about rubber to metal bonding for construction equipment.

- Electronics and Electrical Engineering: Sensitive electronics and enclosures benefit from rubber-bonded metal mounts, EMI/RFI shielding gaskets, and environmental seals. These parts protect circuitry from vibration, dust, water ingress, and electromagnetic interference.

- Medical Devices: Medical pumps, prosthetics, surgical handles, and diagnostic equipment employ precision-bonded rubber to metal parts for durability, flexibility, and biocompatibility. The process ensures precision, chemical resistance, and sterilizability—key for patient safety and hygiene.

- Oil and Gas Industry: Drilling rigs, pipeline connectors, valves, and pressure vessels employ bonded seals, gaskets, and vibration dampers that resist corrosion, high pressure, and chemical attack, ensuring leak-free performance and extended equipment lifespan.

- Railway and Mass Transit: Trains, subways, and trams utilize rubber to metal bonded bushings, suspension systems, and track mountings to improve ride comfort, reduce wear, and dampen noise from constant motion.

- Marine and Offshore: Ships, offshore platforms, and marine engines rely on rubber to metal bonded seals, mounts, and gaskets to combat saltwater corrosion, mechanical stress, and temperature extremes.

- Renewable Energy and Power Generation: Wind turbines, hydroelectric generators, and solar installations employ rubber-to-metal bonded pads, mounts, and gaskets to reduce vibration, prevent leakage, and extend equipment life in challenging outdoor conditions.

Each industry customizes the materials and bonding processes—choosing specific rubber types (such as silicone, nitrile, neoprene, or EPDM) and metals (like steel, aluminum, or copper)—to meet unique performance requirements, including chemical resistance, thermal stability, electrical conductivity, or weight reduction. The adaptability and reliability of rubber to metal bonding make it a preferred solution wherever robust, high-performance, multi-material components are essential.

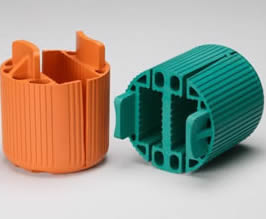

Applications

Rubber-to-metal bonding provides manufacturers with the ability to craft intricate parts of various sizes, serving diverse industries. This versatile process is employed in applications such as:

- Vibration dampening: Reducing unwanted vibrations in mechanical assemblies, vehicles, and machinery.

- Shock absorption: Protecting sensitive components from impact or load spikes in engines, industrial equipment, and electronics.

- Sealing: Creating high-integrity seals and gaskets for automotive, aerospace, oil & gas, and medical applications.

- Friction reduction: Minimizing wear and tear in bearings, pads, and moving assemblies.

- Noise isolation: Lowering noise levels in automotive, industrial, and electronic environments.

- Enhanced grip: Improving traction and ergonomics in pedal surfaces, tool handles, and consumer products.

- Corrosion protection: Shielding metal parts from moisture, chemicals, and environmental degradation.

Typically, the metal-rubber products created through this process find applications across a diverse range of industries, including aerospace, automotive, construction, electrical, industrial machinery, medical, plumbing, rubber rolling, and vibration control sectors. Wondering which rubber to metal bonding solution best fits your operation? Contact an expert to discuss your application requirements.

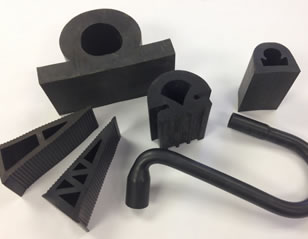

Products Produced

Rubber bonded to metal finds a wide range of applications, reflecting its versatility and adaptability. Common examples include:

- Seals and gaskets: Engineered for leak-proof performance in engines, pumps, and valves.

- Pad surfaces and bumpers: Used in automotive, industrial, and consumer goods for impact protection.

- Pedals and grips: Enhancing ergonomics and control in vehicles, bicycles, and tools.

- Bearings and bushings: Reducing friction and wear in rotating equipment and machinery.

- Engine mounts and suspension bushings: Providing vibration isolation and stability in vehicles and machinery.

- Reinforced tires and rollers: For vehicles, manufacturing lines, and conveyor systems.

- Rubber-lined pipes and tanks: Offering corrosion resistance in chemical processing and fluid handling systems.

- Surgical instrument handles: Delivering grip and comfort in medical tools and devices.

- Electrical cable connectors and plugs: Ensuring environmental sealing and mechanical protection.

In the aerospace and automotive sectors, these components are vital for the installation and functionality of foot pedals, bumpers, steering wheels, engine mounts, and more. Construction and manufacturing industries rely on rubber-to-metal bonding for conveyor belts, gaskets, bearings, and rubber-lined rollers. The medical sector benefits from silicone-bonded elements such as surgical instrument handles, while electrical engineering leverages rubber bonding for cables, plugs, and specialized housings.

History

The evolution of rubber to metal bonding traces back to the early 19th century, marking significant advancements in materials engineering and industrial manufacturing:

- 1830s: Manufacturers first explored natural rubber as an adhesive to join various substrates.

- 1839: Charles Goodyear revolutionized the industry with the discovery of vulcanization—heating rubber with sulfur to enhance elasticity, durability, and resistance to deterioration.

- 1862: Charles Sanderson patented a method for electro-depositing brass onto metal substrates, improving the metal’s ability to form strong, lasting bonds with rubber. This innovation paved the way for more complex and reliable bonded components.

- Early 20th Century: Automotive manufacturers introduced rubber shock mounts, necessitating further innovation in adhesive technologies. The use of crystallized rubber treated with acids led to the creation of solvent-based rubber cements, which soon became the industry standard for bonding applications.

- Late 1920s: Solvent-based adhesives became widespread in the automotive sector for producing engine mounts, bushings, and seals.

- Modern Era: Environmental concerns over solvent-based adhesives drove the transition to water-based bonding agents, which are safer and more eco-friendly. Today, manufacturers leverage a diverse array of adhesives, surface treatments, and metals to deliver optimal rubber to metal bonding performance for advanced engineering requirements.

Materials

Rubber to metal bonding is achieved through the careful interaction of three essential components:

- The metal substrate, providing the structural foundation.

- The rubber material, delivering flexibility and sealing properties.

- The bonding agent, ensuring a durable and lasting adhesion between the materials.

Metal Materials

The choice of metal substrate is pivotal for successful rubber bonding. The substrate must withstand high pressures and elevated temperatures involved in the bonding process, and its composition significantly affects the quality and consistency of the bond.

- Steel: Valued for its tensile strength, durability, and weldability, steel is commonly used for components demanding high load-bearing capacity and wear resistance.

- Aluminum alloys: Increasingly popular for their light weight and cost-efficiency, aluminum alloys offer excellent seal strength and corrosion resistance, making them ideal for automotive and aerospace parts.

- Brass: Appreciated for its aesthetic appeal, low friction, non-sparking, and antimicrobial properties, brass is suitable for electrical, plumbing, and medical applications, though not for high-temperature environments.

- Beryllium: A copper alloy with exceptional electrical conductivity, corrosion resistance, and stability, beryllium is used in demanding electrical and aerospace applications.

- Copper: Renowned for its superb electrical and thermal conductivity, malleability, and antimicrobial qualities, copper is a go-to material for electrical connectors and specialized industrial seals.

Rubber bonding isn’t limited to metals; it can also be applied to non-metals such as fabric, glass, and certain plastics, expanding its application scope across numerous industries.

Rubber Materials

Manufacturers can select from a wide range of natural and synthetic rubbers or elastomers, each tailored for specific performance attributes:

- Nitrile rubber (NBR): Known for excellent adhesion, abrasion resistance, tear strength, and outstanding oil and solvent resistance, nitrile rubber is widely used in automotive, oil & gas, and industrial applications. However, it is less suitable for exposure to highly polar substances.

- Neoprene (CR): A durable synthetic rubber offering strong weather, tear, and abrasion resistance, neoprene is preferred for automotive, construction, cable insulation, and transit applications.

- Silicone rubber: Withstanding extreme temperatures, UV radiation, and ozone exposure, silicone is ideal for seals, O-rings, and gaskets in HVAC, electronics, and medical devices.

- EPDM, SBR, and Natural Rubber: These materials offer a balance of flexibility, cost, weather resistance, and mechanical properties, making them suitable for a variety of industrial and consumer products.

Bonding Agent

Bonding agents are crucial for ensuring secure, long-lasting adhesion between rubber and metal. They are typically categorized as water-based or solvent-based solutions:

- Water-based adhesives: Preferred for their eco-friendly profile and minimal environmental impact, these adhesives offer robust performance and are compliant with increasingly stringent industry regulations.

- Solvent-based adhesives: Still used in select applications requiring rapid cure times or extreme environmental resistance, but increasingly phased out due to health and environmental concerns.

Bonding agents typically include a primer (often phenolic resin-based) and a topcoat containing specialized polymers. The selection of bonding agent depends on the substrate metals, rubber compounds, and the intended service conditions of the final product.

Process Details

The rubber to metal bonding process follows a rigorous, standardized workflow to ensure consistent, high-quality results:

- Rubber Priming: A primer coat is applied to the rubber, usually with a barrel spraying machine, ensuring overlap with the area designated for the topcoat. This step maximizes adhesion and coverage.

- Substrate Cleaning: The metal substrate must be meticulously cleaned using chemical cleaning, sandblasting, or degreasing to eliminate oils and residues—critical for ensuring adhesive effectiveness and bond strength.

- Rubber Molding: The cleaned metal part is placed into a mold, and uncured, heated rubber is injected around it (injection molding). Plated metal inserts may be used to further enhance the bond. This step is also known as insert molding or insert injection molding.

- Rubber Curing: The assembly is subjected to controlled heat and pressure, curing the rubber and forming a permanent chemical bond with the metal. Upon completion, the finished, bonded part is demolded and inspected for quality.

Proper process control ensures uniform adhesion, reliable mechanical performance, and long-term durability of the bonded components.

Design

Effective rubber to metal bonded part design requires careful consideration of:

- Operating environment: Exposure to chemicals, moisture, temperature, and UV radiation.

- Mechanical loads: Anticipated stresses, impact forces, and vibration levels.

- Regulatory standards: Industry certifications and safety requirements (e.g., automotive, medical, aerospace).

- Material compatibility: Optimal selection of rubber, metal, and adhesive for the intended application.

- Coating thickness and number of layers: Determined by expected environmental and mechanical demands.

A thorough design approach ensures that the finished product meets or exceeds performance expectations, longevity, and safety standards.

Variations and Similar Processes

Manufacturers employ several rubber curing and bonding methods, each suitable for different production volumes, part geometries, and performance requirements:

- Chemical curing: Involves applying a bonding agent and allowing it to penetrate at room temperature, often accelerated with heat for field repairs or large parts.

- Exhaust steam curing: Uses controlled steam exposure to cure rubber on the substrate, suitable for large tanks and vessels.

- Vulcanizer curing: Involves placing rubber-bonded metal parts into a live steam vulcanizer, producing exceptionally strong, high-integrity bonds for demanding applications.

- Induction heating: A fast, precise, non-contact method ideal for in-line or high-volume production, especially for small or intricate parts.

Selecting the right curing method is essential for optimizing production efficiency and achieving desired component properties.

Benefits

Rubber-to-metal bonding offers a host of advantages for manufacturers and end-users alike:

- Exceptional bond strength: Provides highly reliable adhesion, preventing delamination under stress or aging.

- Versatility in design: Supports a wide range of part geometries, sizes, and functional requirements.

- Temperature resistance: Enables performance in extreme cold and heat, depending on rubber and adhesive selection.

- Chemical and environmental durability: Withstands exposure to oils, solvents, water, and corrosive agents.

- Noise and vibration reduction: Improves user comfort and equipment longevity by minimizing unwanted vibration and sound.

- Eco-friendly processes: Adoption of water-based adhesives and lead-free materials reduces environmental impact.

- Reduced maintenance and lifecycle costs: Durable bonded parts require less frequent replacement and lower total cost of ownership.

Considering rubber to metal bonding for your next project? Request a quote or consult with our engineering team to evaluate the benefits for your application.

Choosing the Right Manufacturer

Selecting the right rubber-to-metal bonding partner is essential for achieving optimal component performance and value. Here’s how to approach the decision:

- Define your application requirements: Consider your budget, expected order volume, quality standards (such as ISO or automotive certifications), delivery timelines, and any unique performance criteria.

- Shortlist qualified manufacturers: Review companies with proven experience in your industry and the specific bonding processes or materials needed for your parts. Not sure where to begin? Visit our rubber to metal bonding company listings for vetted providers.

- Request technical consultations: Engage with three or four manufacturers to discuss your specifications, application goals, and ask about their production capabilities, quality control measures, and previous project successes.

- Compare proposals: Evaluate cost, lead time, engineering support, and customer service responsiveness.

- Choose the best fit: Partner with the manufacturer offering the ideal blend of quality, expertise, and value for your needs.

Ready to take the next step? Contact us to connect with leading rubber to metal bonding suppliers and receive tailored advice for your project.

Frequently Asked Questions About Rubber to Metal Bonding

- What factors determine the strength of a rubber to metal bond?—Substrate surface preparation, rubber and adhesive compatibility, curing conditions, and part geometry all play significant roles.

- How do I select the right adhesive system?—Consider the specific rubber and metal combination, expected environmental exposure (chemicals, temperature, moisture), and any relevant industry standards.

- Can rubber to metal bonding be used for high-volume production?—Yes, modern processes such as automated insert molding and induction heating are suitable for both prototyping and mass production.

- What are the most common failures in rubber to metal bonding?—Typical issues include surface contamination, improper adhesive application, or mismatched curing cycles. Rigorous quality control and experienced engineering help minimize these risks.

Take the Next Step

Are you researching the best rubber to metal bonding solution for your unique application? Do you need to compare bonding techniques, material choices, or supplier options? Our team of experts can guide you through every phase—from material selection and prototyping to full-scale production and quality assurance. Contact us today to start your project or ask a question.

Related Topics

Whether you’re designing components for automotive, aerospace, industrial, or medical applications, rubber to metal bonding remains a cornerstone technology for achieving high-performance, durable, and efficient products. With the right materials, process expertise, and manufacturing partner, your bonded parts can deliver exceptional results in even the most challenging environments.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services