Rubber and metal are frequently glued together because metal adds strength to rubber goods. In a rubber-metal connection, the metal may act as a fastening component. The two materials are glued together to create a single product that combines strength and flexibility. Read More…

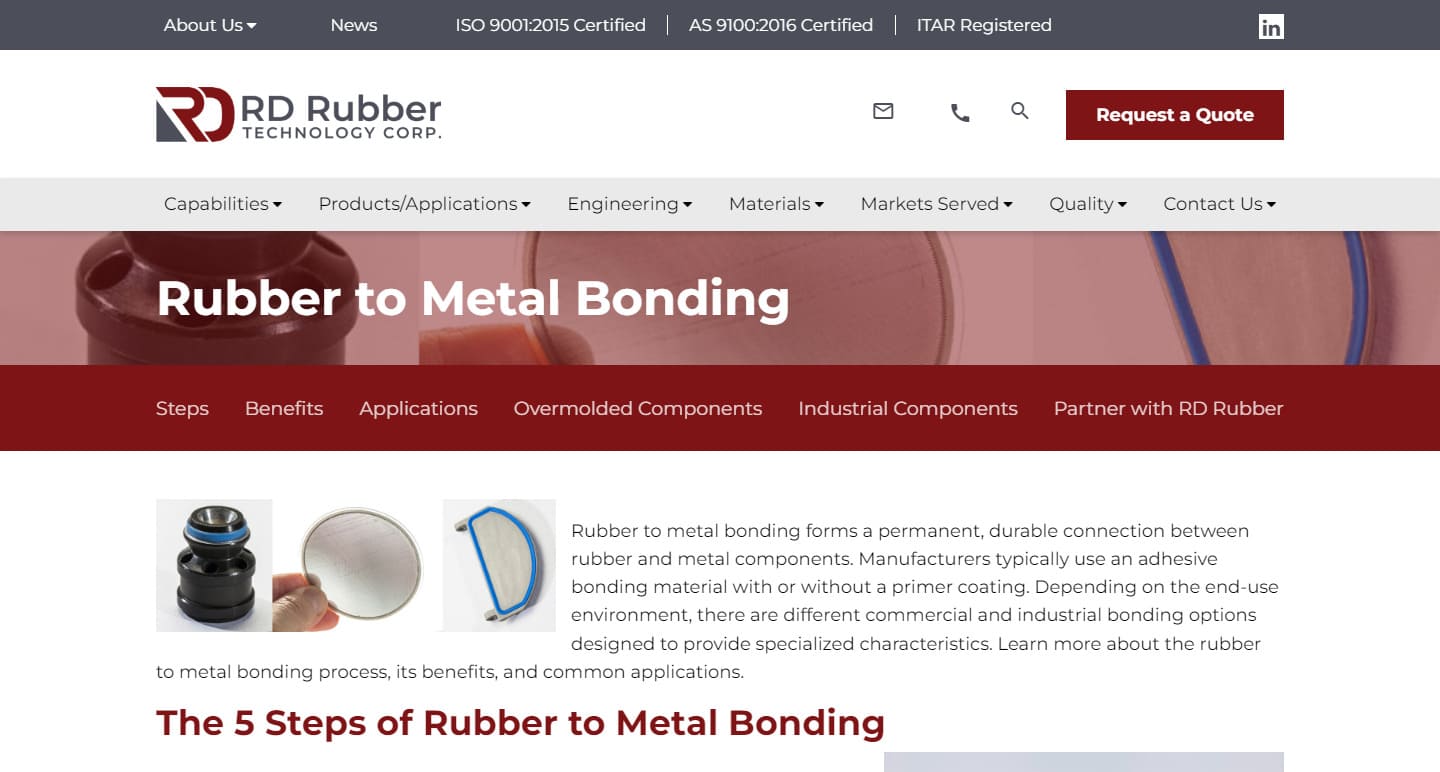

RD Rubber Technology is an ISO 9001:2015 certified company that is highly responsive and flexible to customer needs. We can take care of design, development, and prototyping as well as short run, long run, and high volume production. We offer compression, transfer, LIM, and rubber to metal bonding. We also do silicone to thermal plastic bonding.

Since 1984 we have been providing excellent high performance solution to our client’s toughest bonded metal to rubber issues. Our skilled teams of engineers and technicians will work closely with you in order to ensure that we are filling your exact requirements on the products that we provide. Allow us to show you the difference when you work with true experienced professionals. Visit our...

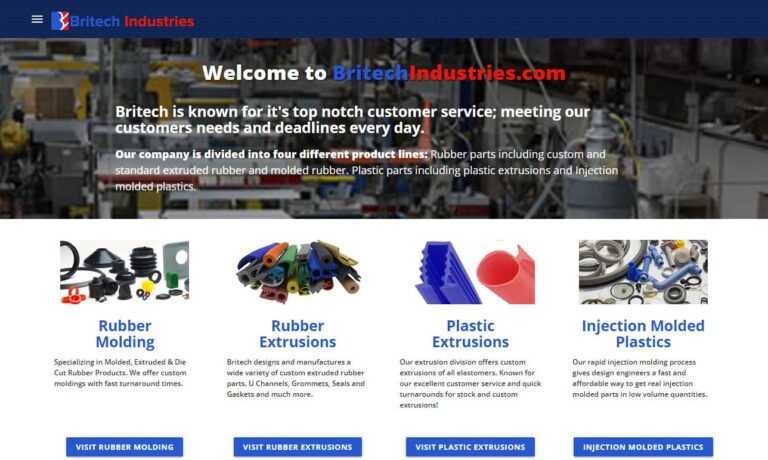

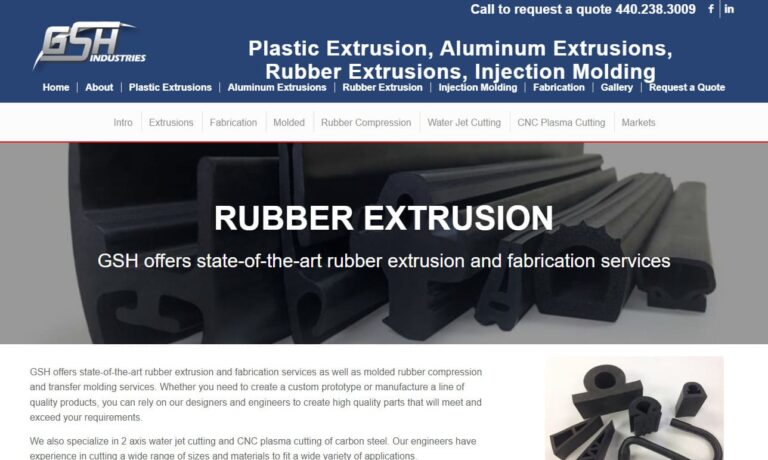

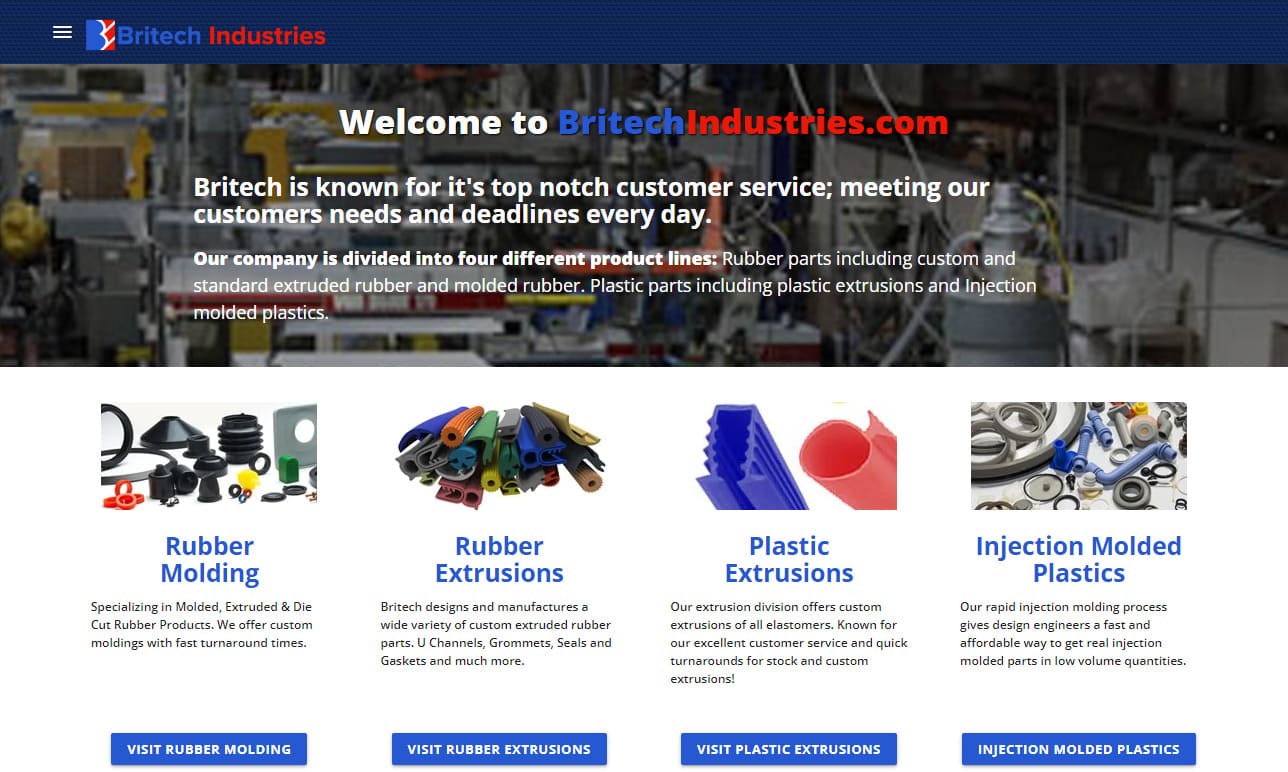

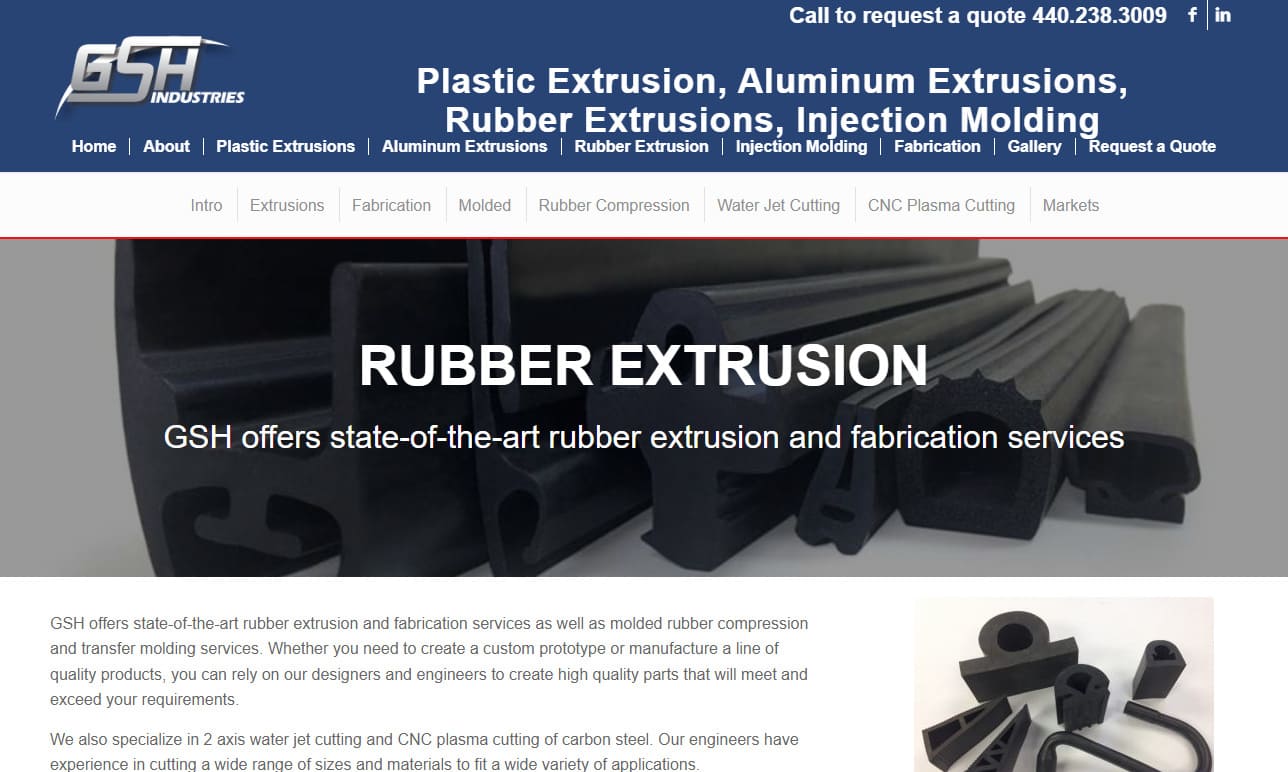

For over 25 years, GSH has provided top quality contract manufacturing services, and we strive to remain on the cutting edge of our industry.

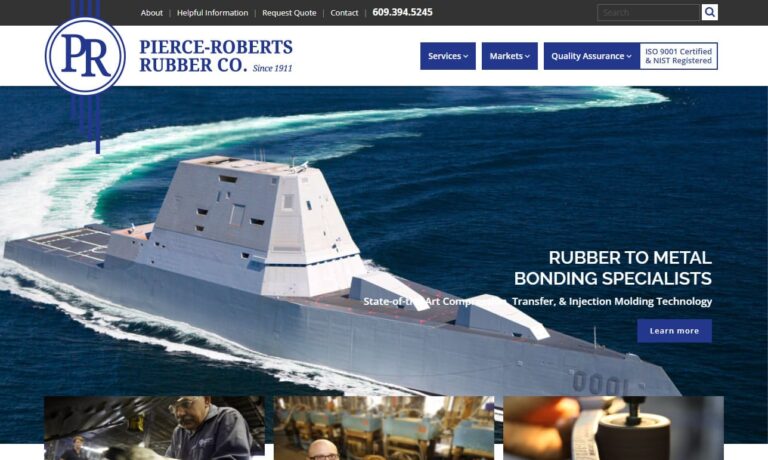

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

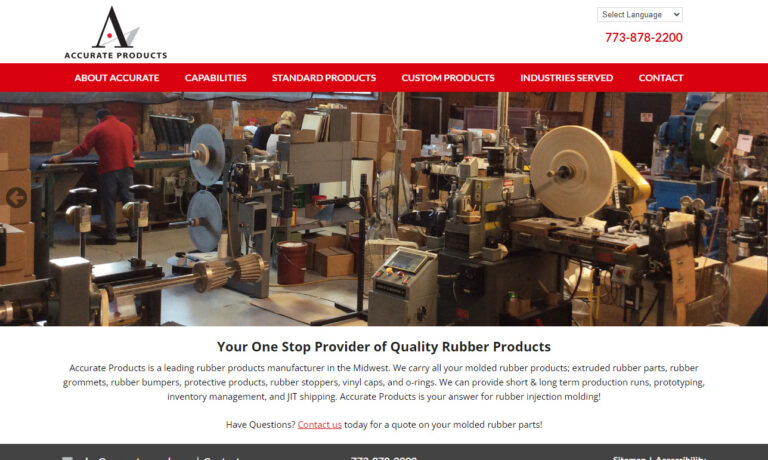

See how Accurate Products can bond natural and synthetic rubber to a wide variety of materials for applications such as tires, gaskets, seals, rolls, hoses, tubes, vibration isolators, shock mounts, electrical components, bumpers, drive wheels, etc.

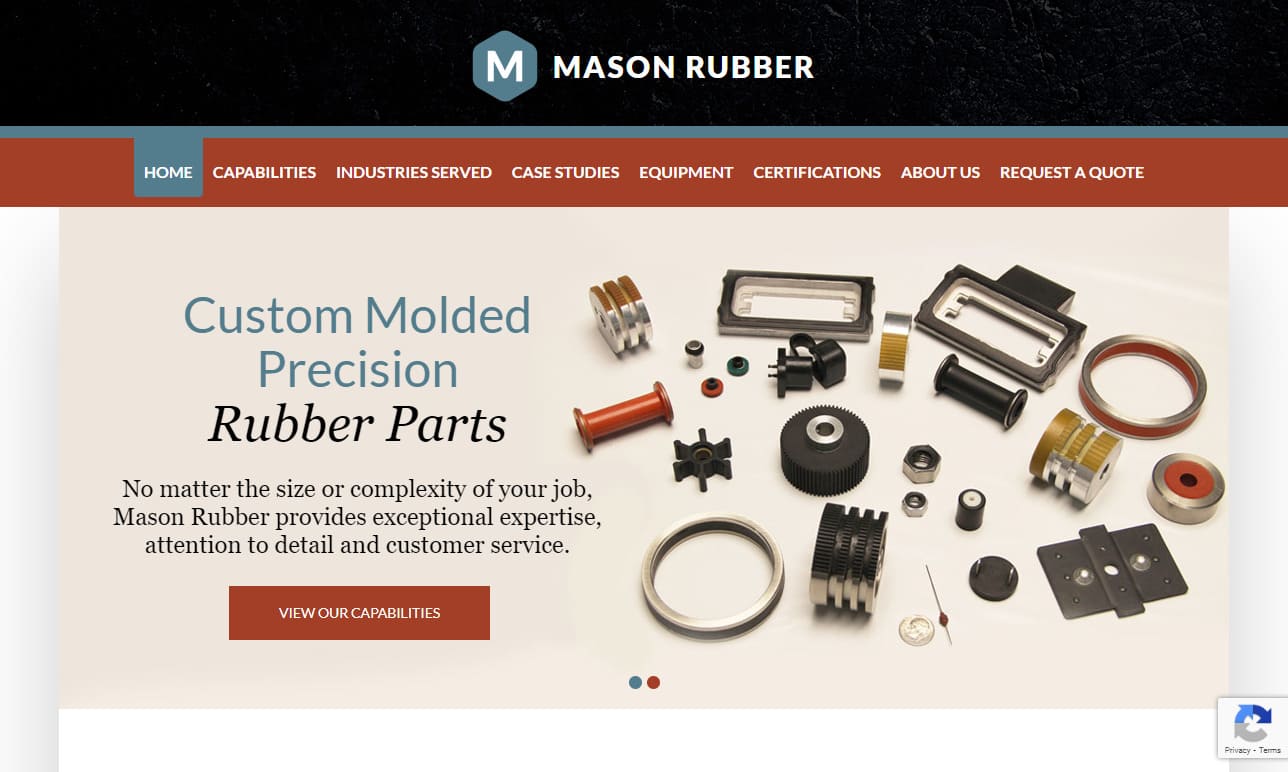

From molding products made of homogeneous rubber, to rubber bonded to metal as well as other various materials. Mason Rubber makes efficient use of state of the art technology to produce a quality product.

Our economical products are made from high-quality solutions that will last you for many years to come. We are a dependable manufacturer that will work with you every step of the way.

At National Rubber Corp., we specialize in advanced rubber-to-metal bonding solutions designed to meet the demanding requirements of diverse industries. With extensive expertise and precision manufacturing capabilities, we produce durable, high-quality components that seamlessly integrate rubber materials with metal substrates.

Since 1955, Jet Rubber Company, an Employee Owned Company, has been custom molding rubber and rubber-to-metal components for a variety of industries and applications.

More Glue Rubber to Metal Manufacturers

Choosing Proper Types of Glue

When attaching rubber to metal, success depends on choosing the best glue for the task. The best adhesive for rubber can be difficult to choose because manufacturers offer a variety of adhesives. Rubber can be adhered to metal using multiple types of glue, but only some of them will produce the desired outcomes.

Superglue or Instant Glue

Superglue or instant glue is the best adhesive for rubber to metal. They are dry, transparent, and won't interfere with other materials in the project. These adhesives have a rapid drying period and are adaptable to any project. These adhesives make strong yet brittle bonds. They don’t create bonds that endure consistent strain.

Epoxy Glue

Epoxy adhesives are best for forming stronger bonds. Once dry, they form a permanent bond that cannot be broken without specialized equipment. Epoxies take longer to dry than quick glue. If one wants to have areas of rubber visible on the finished creation, there are better solutions than this because it can also dry with an impenetrable hue.

Glue stick

Glue sticks are ideal for tasks requiring very little glue or where extremely accurate placement is necessary. Glue sticks do not require glue guns, making them safer to handle. However, they take longer to dry than instant or super glues.

Rubber Cement

Rubber cement can be used when applying rubber to metal but does not want it to adhere firmly. Rubber cement is excellent when crafting with children because it simplifies playtime clean-up.

Glue gun

Glue guns should only be employed in temporary situations. They will leave behind a tacky residue once dry, and to have a clean finish, this residue needs to be cleaned. Glue guns also have a longer drying period.

Steps to Glue Rubber to Metal

Rubber Preparation for Glue

Start by cutting pieces of rubber that have smooth edges and are free of any blemishes or holes. After that, try each piece of rubber on the item. Next, apply a degreaser to the metal and rubber surface to clean it, and then properly dry it. Additionally, one should set up the work area before applying glue with wax paper to protect surfaces and ensure an easy cleanup.

Put the Adhesive On

To decide whether to apply the glue to one or both surfaces, one should refer to the glue's container or manufacturer's instructions. Regardless of the glue type, it must be placed in a thin layer with no visible bubbles or clumps. Next, use the applicator brush the glue may have come with to help spread any extra glue and provide a smooth, finished appearance.

Put the Two Surfaces Side by Side

Once there is sufficient glue, one should unite the rubber and metal by pressing them forcefully for a short period to form a solid bond between the two components. Hold the two until it is set. If more time is required, hold the two pieces together until the adhesive is set with the help of heavy objects or a clamp.

Let it air-dry

Depending on the adhesive used, the curing process can take anywhere from 10 minutes to 24 hours for the glue to complete. Therefore, wait until the components are totally dried and set together before continuing with the project.

Choosing the Right Company that Glues Rubber to Metal

To make sure you have the most productive outcome when selecting a company that glues rubber to metal, it is important to compare at least 4 companies using our list of companies that glue rubber to metal. Each glue rubber to metal company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each glue rubber to metal company using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple companies that glue rubber to metal with the same message.

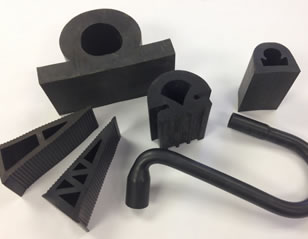

Rubber Extrusions

Rubber Extrusions Rubber Molding

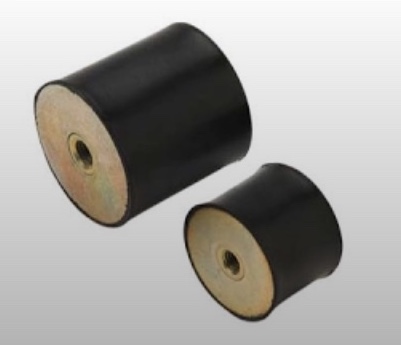

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

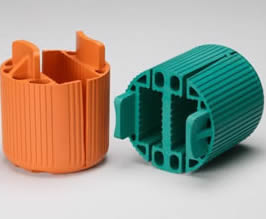

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services