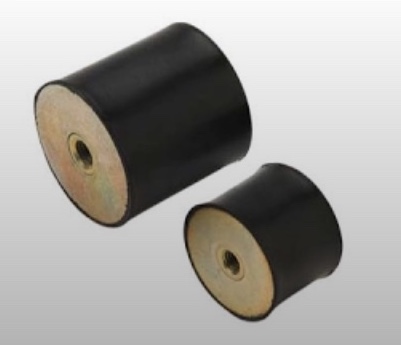

Durability is probably the most important characteristic of many products and is especially important for parts with rubber to metal bonding. The automotive industry uses rubber bonding on parts to absorb and dampen sound; this is one of the most common applications in the field. So how is durability ensured in the specific instance of these particular products? Well, there are a few different issue that could lead to failure as well as different ways to prevent them.

When it comes to rubber to metal bonding, molds must be designed in a way that supports an exact balance between cavities and the displacement of trapped gases. The goal in achieving this balance is to prevent what is referred to as the “diesel effect,” which causes bond failure as the effects of high pressure gas and heat cause elements of the bonding agent film to burn. Imbalance between cavities lead to components that are imperfectly formed, which, in turn, causes bond failure.

One way to avoid this specific problem is to study the flow of rubber through the mold with computer flow simulation packages. These programs model the reaction of pressure gradients to mold design and the cross linking response of the rubber. Computer analysis such as this often results in optimum molding conditions and runner sizes before the mold is produced, resulting in components that a manufactured to specification.

Using plated inserts is also common with certain designers. This approach can result in the production of good bonds, but if the bond edge is frequently exposed to electrolytes then problems may occur. For instance, salt solutions from streets can create “battery” cells between the carbon black in the rubber and the plated metal. Nascent hydrogen at the electrode surface causes cathodic disbondment which will eventually lead to failure. Being aware of these potentials issue and how to prevent them is important in the production of high quality rubber to metal bonding products.

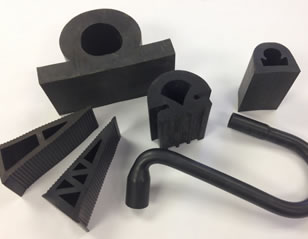

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

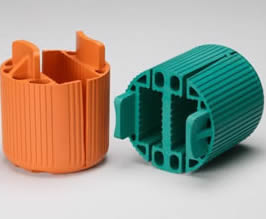

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services